In the laboratory, the cleanliness of glassware directly determines the accuracy and credibility of experimental results. A test tube that appears clean might still harbor microorganisms from the previous experiment, and a newly unsealed flask could carry manufacturing impurities. These hidden risks make thorough cleaning before autoclaving crucial—not only to ensure the effectiveness of sterilization but also to effectively prevent potential contamination, serving as the fundamental defense for the smooth conduct of experiments.

Removing Residue: First, pour out or scrape off as much residue as possible from the glassware. For residues that are difficult to remove, soaking or dissolving them with appropriate chemical reagents can be used.

For example, for greasy residues, an alkaline solution can be used for soaking; for protein residues, an enzyme solution can be used for soaking.

Soaking: Soak the glassware in warm water containing detergent, with the water temperature generally controlled at 40-50℃. The soaking time depends on the level of contamination of the glassware, generally ranging from 30 minutes to several hours. Soaking can soften the dirt, making it easier to be washed off.

Select the appropriate brush: Choose a suitable brush based on the shape and size of the glassware. The bristles should be of moderate hardness; too hard, and they will scratch the glass surface, too soft, and the cleaning effect will be suboptimal.

Scrubbing method: Dip the brush in detergent and carefully scrub the inner and outer surfaces of the glassware. Make sure to scrub every corner of the glassware, especially areas like the mouth, bottom, and walls of the containers where dirt tends to accumulate. Apply even pressure while scrubbing to avoid scratching the glass.

Rinse with tap water: Thoroughly rinse the glassware with tap water to wash off the detergent and dirt. Ensure that the water flow reaches every part of the glassware, and rinse for no less than 3 minutes.

Rinse with purified water: To further ensure the cleanliness of the glassware, use purified water for the final rinse. Rinsing with purified water can remove impurities and ions from tap water, thus avoiding any interference with experiments.

Air drying: Invert the cleaned glassware on a clean rack to let it dry naturally. This method is simple and convenient but requires a longer time.

Oven drying: If time is pressing, place the glassware in an oven for drying. The oven temperature is usually controlled at 100-120℃, and the drying time depends on the size and number of glassware, generally 1-2 hours.

Select appropriate packaging materials: Choose suitable packaging materials based on the size and shape of the glassware. Commonly used packaging materials include kraft paper, aluminum foil, and specialized sterilization bags. The packaging materials must withstand high temperatures and pressures without releasing harmful substances.

Packaging method: Place the dried glassware in the packaging materials and seal them. Ensure not to over-pack to avoid affecting the sterilization effect. Additionally, label the package with the item name, sterilization date, and other pertinent information for easier tracking and management.

Loading: Place the packaged glassware into the autoclave, ensuring not to exceed the autoclave's load capacity, to maintain effective sterilization.

Sterilization parameters: Set the appropriate sterilization parameters based on the material and contamination level of the glassware. Typical laboratory sterilization parameters are: temperature 121℃, time 15-30 minutes.

Cooling: After sterilization, wait for the autoclave to cool down to a safe temperature naturally before opening it to retrieve the glassware. Avoid sudden cooling to prevent the glassware from cracking.

Personal protection: Wear personal protective equipment throughout the cleaning and handling process, such as lab coats, gloves, and goggles, to avoid exposure to harmful substances or injury.

Avoid cross-contamination: Prevent cross-contamination between different glassware during the cleaning and handling process. Thoroughly disinfect glassware that has been used for cultivating microorganisms.

Regular inspection: Regularly check the performance of cleaning and handling equipment to ensure they are functioning properly. Replace cleaning and disinfecting agents periodically to avoid inefficacy.

Follow these steps, and your glassware will become "as good as new," and your experimental data will be more reliable! If you find this useful, don't forget to like, bookmark, and share it with your lab partners!

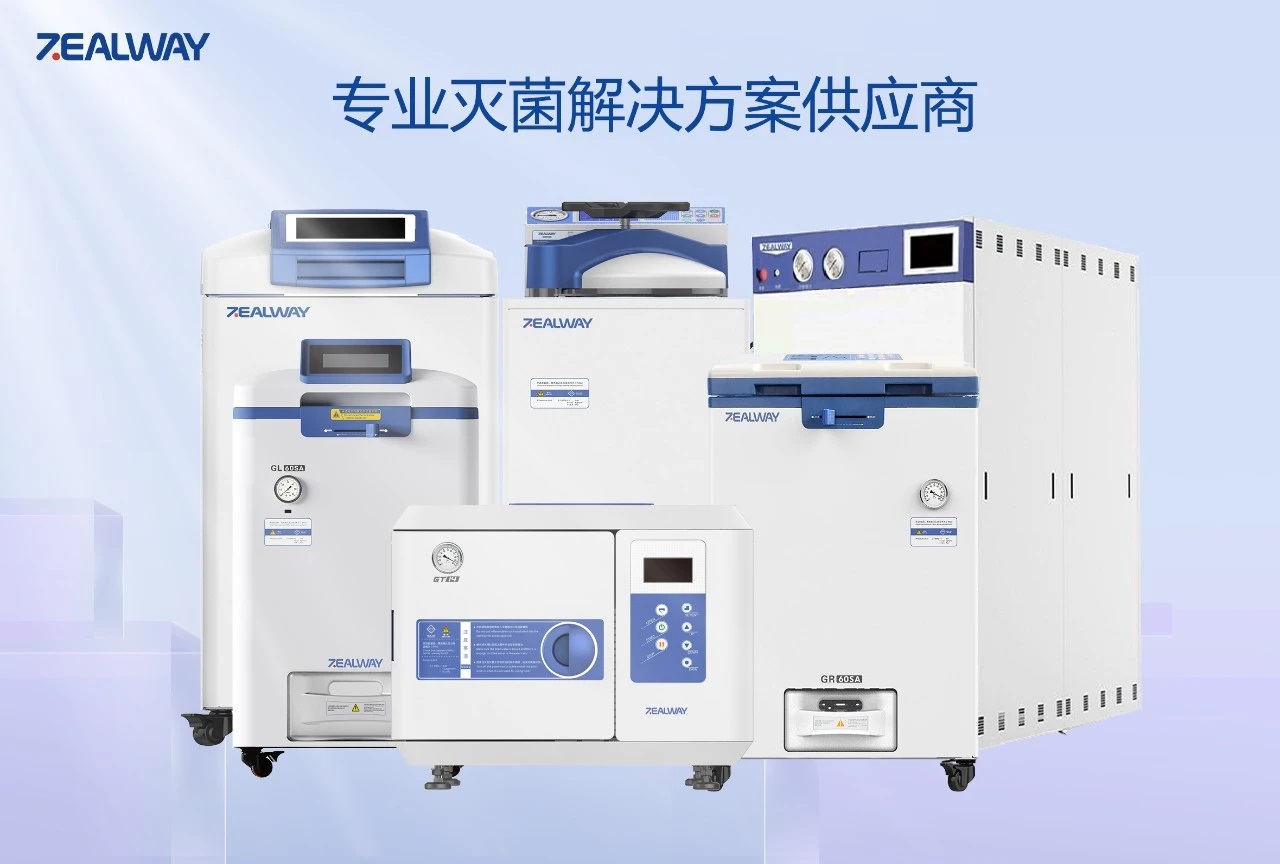

At Zealway, we see the future

At Zealway, we are committed to becoming the best autoclave manufacturer globally. For over 20 years, we have remained focused on the R&D, manufacturing, application, and service in the field of sterilization equipment, dedicated to providing one-stop solutions to customers with high requirements for safety, quality, and performance.

This is the first one.