In fields such as laboratories, clinics, and food processing, autoclaves are the "core equipment" for ensuring sterile safety of items. However, facing the diverse range of models on the market, many purchasers are often confused: what are the differences between benchtop, vertical, and horizontal autoclaves? Which one best meets their usage needs? As a manufacturer with years of experience in autoclave equipment, today we will provide a comprehensive breakdown from key dimensions such as capacity, scenarios, and cost, to help you make the right choice without pitfalls!

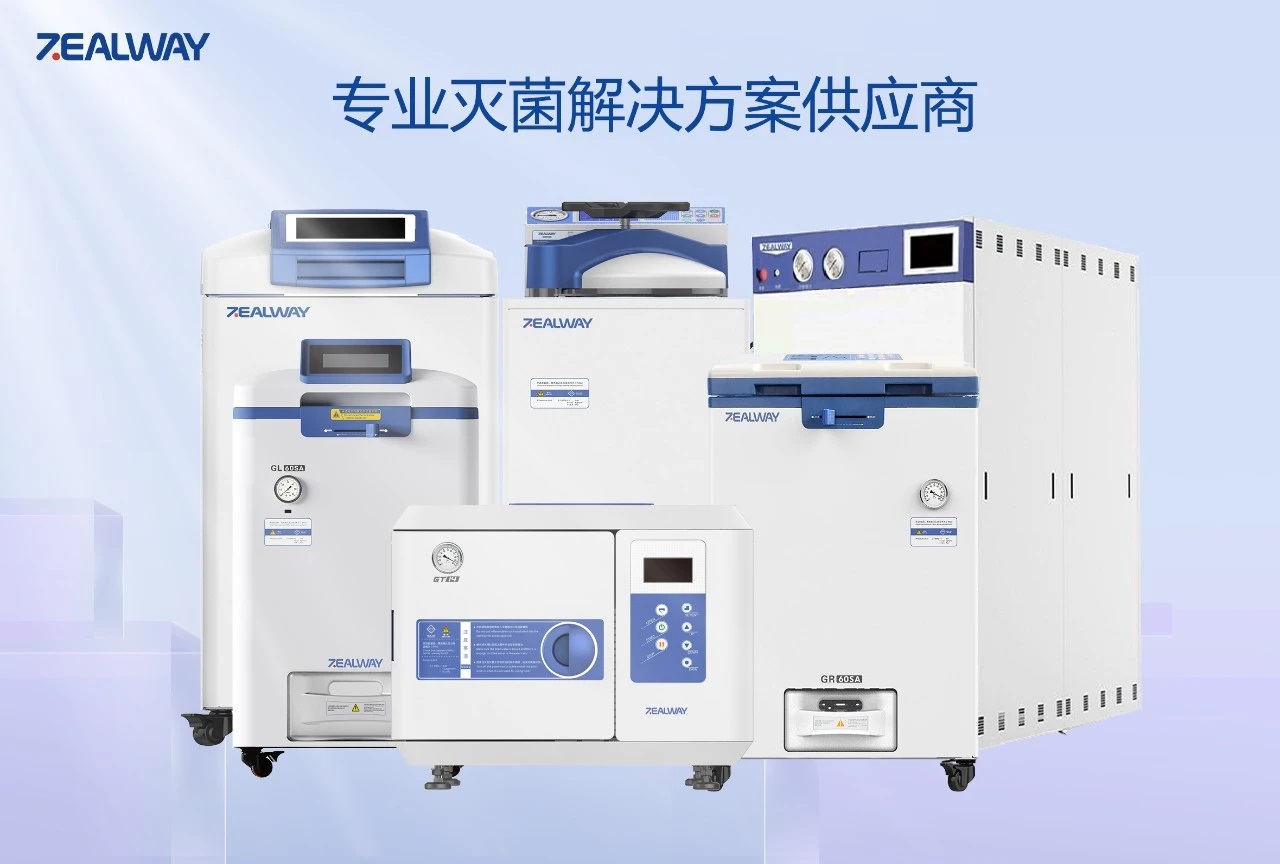

Zealway Autoclaves

Comparison Dimension | Benchtop Autoclave | Vertical Autoclave | Horizontal Autoclave |

Capacity Range | 18-23L+ | 29-175L+ | 180-350L+ |

Floor Space | Small (can be placed on a lab bench) | Medium (floor-standing, occupies 1-2㎡) | Large (needs reserved independent space) |

Sterilization Objects | Test tubes, petri dishes, small instruments | Medium instruments, culture media, reagents | Large equipment, bulk materials, turnover baskets |

Applicable Scenarios | Small laboratories, clinics, PCR rooms | Medium laboratories, hospital departments, food testing stations | Large pharmaceutical companies, hospital sterilization supply centers, university training bases |

Characteristics

Small size, takes up little space, can be placed on countertops or mobile racks.

Usually small capacity, suitable for small batch sterilization.

Simple operation, suitable for routine disinfection.

Applicable Scenarios

Small laboratories, clinics, dental clinics.

Places that need frequent small-scale sterilization, such as school teaching laboratories.

Advantages

Relatively low price, suitable for users with limited budgets.

Easy to install, no special modifications needed.

Limitations

Limited capacity, cannot handle large amounts of items.

Characteristics

Capacity is between benchtop and horizontal types, suitable for medium-scale sterilization needs.

Compact design, vertically placed, saves floor space.

Applicable Scenarios

Medium laboratories, hospital test departments, biotechnology companies.

Users needing to handle a variety of items, such as culture media, instruments, and liquids.

Advantages

Moderate capacity, meets most daily needs.

Rich in functions, highly flexible.

Limitations

More expensive than benchtop types, suitable for users with certain budgets.

Needs some installation space.

Characteristics

Large capacity, can handle a large amount of items at once.

Usually equipped with advanced control systems and safety devices.

Suitable for high-intensity, large-scale sterilization tasks.

Applicable Scenarios

Large hospital central supply rooms, pharmaceutical factories, industrial-grade laboratories.

Places needing to handle large amounts of instruments, culture media, or waste.

Advantages

Efficient and time-saving, suitable for high-intensity use.

High degree of automation, reduces manual operations.

Limitations

Takes up a lot of space, requires a dedicated area.

Higher cost, suitable for users with ample budgets.

Still not sure how to choose after reading the above analysis? Don’t worry, remember these three steps to easily lock in your answer:

Calculate Capacity: First tally the total amount of items needing sterilization daily and the maximum size of a single item. Choose a capacity based on "actual needs + 20% allowance" to avoid insufficient use from buying too small and waste of money from buying too large;

Check the Space: Measure the length, width, and height of the available space. For a benchtop unit, reserve countertop space; for a vertical unit, reserve floor space; for a horizontal unit, consider the door opening direction and passage width;

Set a Budget: The budget for a benchtop unit is relatively low, moderate for a vertical unit, and higher for a horizontal unit (including installation and maintenance costs). Balance your choice based on your budget and long-term usage needs.

Tip: If your usage scenario is more complex (e.g., you need both small-batch sterilization and occasionally bulk sterilization), consider a "benchtop + vertical" combination purchase for flexibility and efficiency!

As a manufacturer focused on the research, development, and production of autoclaves, we always believe that "there is no best equipment, only the most suitable equipment." If you have any questions during the selection process, feel free to contact us—provide your usage scenarios and needs, and we will tailor a customized sterilization solution for you!

Zealway is dedicated to making the best autoclaves in the world. For over 20 years, we have been focused on the research, development, manufacturing, application, and service of sterilization equipment, committed to providing one-stop solutions to customers with higher requirements for safety, quality, and performance.