In the practice of sterilization validation, have you ever fallen into the pitfalls of "temperature only" or "time only"? The true, verifiable aseptic state goes far beyond a set temperature value. This article will take you beyond the surface of 121°C to explore the three core dimensions of sterilization efficacy: effective steam contact, precise energy maintenance, and sufficient duration of action. Starting from these core elements, we aim to build a robust aseptic assurance system, creating a genuine sterile defense line.

The penetration and sufficient contact of steam are prerequisites for successful sterilization. If the steam cannot reach the microorganisms, no matter how high the temperature or how long the time, sterilization cannot be achieved.

Key Points

Expel all air: The principle of pressure steam sterilization is to use the latent heat released by saturated steam during condensation to achieve sterilization. If there is air in the sterilization chamber, it will form "air pockets", hindering the contact between steam and item surfaces. Therefore, an effective exhaust procedure (such as pulsation vacuum, downward exhaust) must be implemented to ensure complete removal of air.

Standardized Loading

There should be appropriate gaps between items, and packaging materials must facilitate steam penetration (like specialized non-woven fabrics, paper-plastic pouches).

Bowls, pans, and other utensils should be placed tilted or upside down to avoid air and moisture accumulation.

Heavy instruments should be dispersed and not stacked too tightly to avoid hindering steam circulation.

Choose suitable packaging: Do not use closed, non-breathable containers (like aluminum lunch boxes or sealed glass bottles), as steam cannot enter them.

Temperature is the core factor for inactivating microorganisms. Different microorganisms have varying heat tolerances, and it is crucial to reach their heat-lethal temperature to ensure their death.

Key Points

Common temperature standards:

121°C: The most commonly used sterilization temperature, suitable for most medical instruments, culture media, and waste. At this temperature, all microorganisms, including bacterial spores, can be killed.

134°C: Ultra-high temperature sterilization, which requires a shorter action time, often used for instruments requiring quick turnaround (like surgical instruments).

Temperature Monitoring

Physical Monitoring: Observing the temperature display instrument on the sterilizer to confirm the pre-set temperature is reached.

Chemical Monitoring: Using internal and external chemical indicator cards/tapes to judge if the temperature has been reached based on color changes.

Biological Monitoring: Regularly using indicators containing Bacillus stearothermophilus spores, which is the "gold standard" for validating sterilization efficacy.

After reaching the specified temperature, sufficient time must be maintained to ensure the heat thoroughly penetrates the items and continuously acts on all microorganisms.

Key Points

Sterilization time: The time calculated starts after the center of the items reaches the set temperature, excluding the heating up and air-exhausting time.

Typical time at 121°C: Usually needs to be maintained for 15-30 minutes (specific time depends on the nature of the items, packaging, and load volume).

Typical time at 134°C: Usually needs to be maintained for 3-10 minutes.

Influencing Factors

Nature of items: Liquids, porous items, and heavy instruments require longer sterilization time as heat takes longer to penetrate to the center.

Packaging and Load: Overly large packaging or overly dense loads will prolong heat penetration time, thus necessitating an extension of the total sterilization time.

Summary: All three are indispensable

Effective pressure steam sterilization is a systematic project where contact, temperature, and time are interrelated, forming a complete sterilization cycle:

Adequate contact is the foundation, ensuring steam reaches all surfaces;

Sufficient temperature is the core, providing energy to kill microorganisms;

Necessary time is the guarantee, allowing the heat energy to act continuously and thoroughly inactivate.

Strict adherence to the operating procedures of pressure steam sterilization, precisely controlling the three key conditions of contact, temperature, and time, is the only way to truly ensure the reliability and safety of each sterilization process, safeguarding sterilization safety and product quality.

Warm Reminder

The specific sterilization parameters may vary for different models of sterilizers and different types of items. Be sure to follow the equipment manual and relevant industry standards for operations.

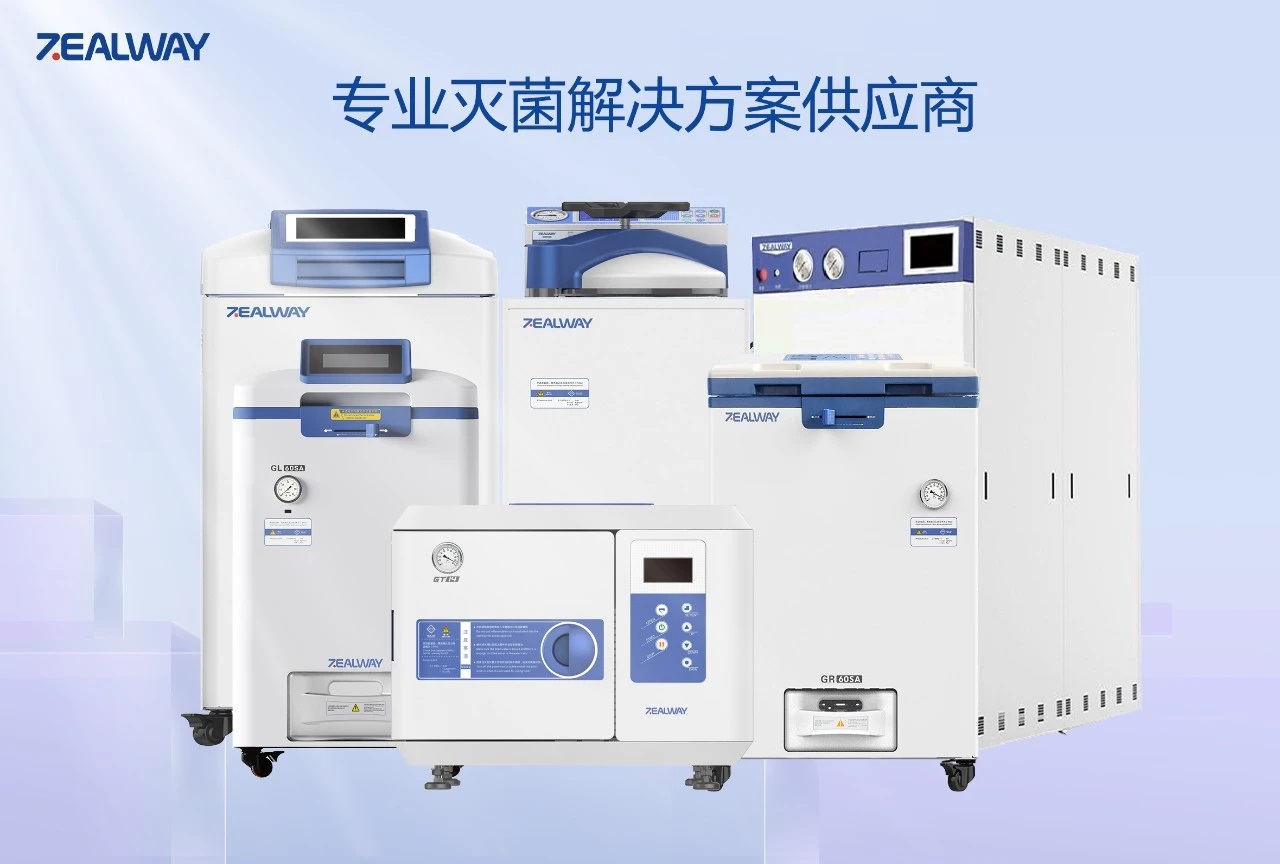

Zealway is committed to being the world's best autoclave manufacturer. For over 20 years, it has focused on the research, manufacturing, application, and service in the field of sterilization equipment, striving to provide one-stop solutions to customers with higher requirements for safety, quality, and performance.